- CTP wastewater treatment equipment

- Light guide plate equipment

- Automatic Sticker Machine

- Non - Standard Automation Equipment

- Connector Industry Automation Equipment

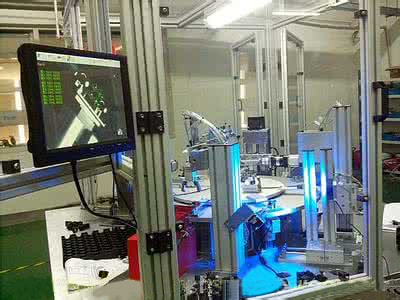

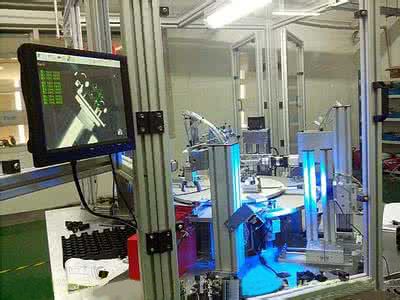

- Fully Automated Production Lines

- Test Fixture Series

- Tooling Carrier Series

- The first division (standard machine)

Contact information

DongGuan MSA Intellingent Technology Co.,LTD

Contact: Mr. Cai

Mobile:13650018949

Contact: Mr. Zhang

Mobile:13809627148

Tel:0769-81111739

Fax:0769-81621070

E-mail:msamg@msasmart.com

Website:9000mgyf.cn

Add:1st Floor, Yunding Technology Innovation Park, No. 22, Farm Industry Road, Dalingshan Town, Dongguan City

Connector visual inspection equipment

Connector, also known as the terminal, is an indispensable part of electronic equipment for mobile phones, computers, portable electronic devices. The connector makes the production of these electronic devices more convenient and faster, while also reducing production and maintenance costs. However, with the increase in the function of the device, the volume of the ever-decreasing, the quality of the connector requirements are getting higher and higher. Connector production process, the product quality testing link has been restricting the improvement of production efficiency, due to the particularity of the product, a lot of product testing are by manual detection, no specific amount of expression, in the case of eye fatigue is also easy Produce a false check. In order to prevent the failure of the connector into the subsequent product assembly, most of the connectors are required to use the full inspection of the follow-up detection. Visible, the quality of the connector is a very important part of the test! However, the accuracy, objectivity and stability of manual testing have been plagued by the connector manufacturer. Based on the machine vision of the optical automatic detection method, in the connector detection, play an increasingly important role. The use of visual equipment to improve product quality and stability, reduce labor costs have a great advantage.

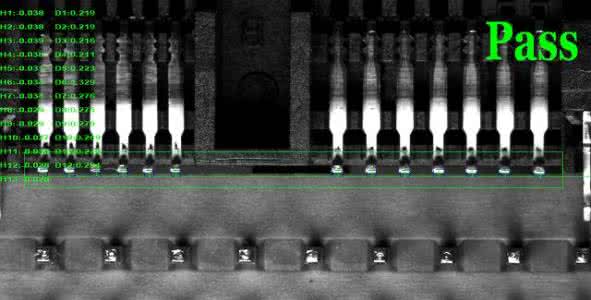

Second, the system function (customer sample) Our development of visual technology based on the connector detection equipment is a high-precision, high-speed semi-automatic detection equipment, specifically designed to detect the appearance of a variety of connector terminals, pin flatness, cited Foot spacing and other parameters. System using manual feeding method, simply set, you can automatically identify, detect. If an exception occurs, can provide light or buzzer and other alarm signals. The system can also be equipped with measurement data storage, analysis and printing functions. The device interface contains real-time image detection information, clear and intuitive, you can accurately and quickly complete the test, significantly improve work efficiency and product quality! Automatic detection, automatic recognition in the image on the basis of automatic incoming ---- automatic detection ----- automatic rejection. Three steps to complete the automated production. Combined with the production site environment for users to develop automatic production solutions.

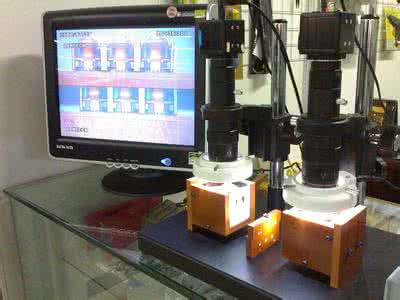

Third, the product description This machine for manual detection, the display can display two to eight lines as a benchmark, through the CCD zoom imaging, mobile table adjustment to achieve the purpose of testing. Now on the basis of the original, improved the CCD part, from the traditional analog signal to digital signal input, the camera built-in cross-line generator, the line finer, more convenient and quick adjustment.

Fourth, the main technical characteristics and advantages

1. Detection accuracy, can reach 0.01 mm detection accuracy, repeatability can reach 0.005 mm;

2. Light source layout clever and reasonable, for the collection of good image data source to provide protection. Light source using LED light source, long life, high stability, good consistency, low maintenance costs.

3. Using high-resolution CCD camera, easy to achieve external trigger control functions;

4. The main visual devices are imported parts, with long life, stable performance, anti-interference ability and other advantages;

5. Using 1394 interface CCD camera, simplify wiring, and save the CCD external power supply, maintenance is very convenient; Easy to use interface.